I can’t wait to continue the cloth simulation.

In recent weeks we have created a 3D scene ready to simulate fabric. However, before continuing, it may be useful for us to understand fabric.

A few questions come to my mind 🤔:

- What are the materials used ?

- What are the physical properties?

- How is it made?

Each fabric is different. The material used will change its properties. The construction process (weave? knit? etc.) will change its properties. To be frank, changing any of these variables should change the behavior of the final simulation because the fabric itself is different.

That said, a question that we must always ask ourselves before simulating something is:

What am I simulating?

This article will answer that question in regards to fabric. 👕

The raw materials of fabric 🧶

The three main material categories are those derived from plants, those from animals, and those that are man-made.

Common materials are:

- Cotton - Cotton as a fabric is durable, soft, and warm. It is made of short plant fibers that are spun together to form longer threads. It wrinkles easily.

- Linen - from the flax plant. Linen as a fabric is breathable, lightweight and moisture wicking. It is made of short plant fibers that are spun together to form longer threads. Flax fibers do not stretch. Linen is known to wrinkle easily: this is because it has low elasticity.

- Silk - from the silkworm cocoon. Like wool, it is a protein-based fiber. Strength is one of the most interesting characteristics of silk in addition to its resistance to wrinkle.

By Neri Oxman - Mediated Matter Group, CC BY-SA 4.0, Link

- Wool - harvested from sheep. Wool is supple, elastic and strong- which makes it durable and wrinkle-resistant.

- Polyester - made of a man-made filament that is usually derived from petroleum. Polyester fibers are incredibly strong, which means they won’t tear or stretch like cotton and other natural fibers. Polyester is wrinkle resistant.

By Bearas - Own work, CC BY-SA 4.0, Link

The fabrication process 🧵

With our raw materials, we are almost ready to manufacture the fabric. There are several methods to create fabric as we know it, such as weaving or knitting.

First, we will see how the fibers are transformed into threads. For the next few examples, let’s assume we’re following the fabrication process of one of the most used materials in fashion and textiles - cotton.

Spinning from fiber to yarn

After growing, harvesting, separating and ginning cotton, it’s time to form a thread.

By spinning fibres, yarn is made. The idea is that this process holds the fibers firmly together.

By Marion Scheffels - Self-photographed, CC BY-SA 3.0 de, Link

There are two properties of yarn that will change its character:

- Twist - the direction in which it has been spun or twisted.

- Z-twist: the thread is spun or twisted clockwise.

- S-twist: the thread is spun or twisted anti-clockwise.

- Ply - The ply is the number of yarns that are twisted together to form a single yarn. Two or more spun yarns can be twisted together to form a thicker yarn which is then woven into the fabric. Two-ply fabrics are generally superior to single-ply fabrics

What spinning methods exist?

In the past, the vast majority of spinning was done with a spinning wheel. The fibers are pulled through a wheel and as it spins the fibers are collected on a cylindrical object called a spool.

Nowadays, spinning methods are more complex thanks to technological advancements although the general idea remains the same. Here is this resource to learn more.

Weaving

To weave the threads, we use a loom. I swear, the videos on how to use it are truly a pleasure to watch.

After weaving on threads with a loom, we should have fabric that we can use as we please! 🥳

If we look closely at a woven fabric, we would only see the lines of threads interwoven perpendicularly. The longitudinal threads are called warp threads and the perpendicular threads are weft threads.

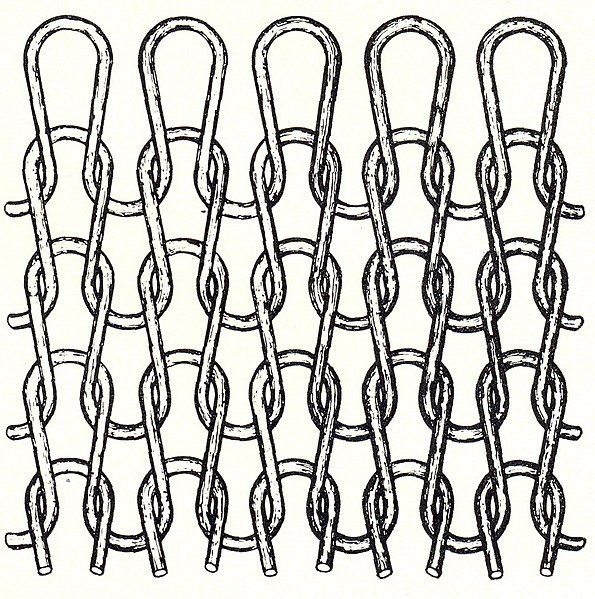

Knitting

Of course, there are other ways to make fabric. For example, knitting is very popular.

It is made up of stitches which are loops of threads that intertwine. The knitter makes the knit with the help of needles. 🪡

Knitting versus weaving

There are two important points to keep in mind when simulating these fabrics:

- Stretchiness - A knit fabric can stretch more than a woven fabric.

- Resistance - A knitted fabric stretches in all directions which gives it a supple character while the weave limits movement, especially in the vertical direction.

Next time

We will see how to model the physical forces that are in a piece of fabric.

Resources

- How to make fabrics: The basics - The Sustainable Fashion Collective

- How is fabric created? - HowStuffWorks

- Filature textile - Wikipédia

- Textiles techniques - Daniel Weidmann

- Spinning wheel - Wikipedia

- The Special Properties of Silk - ComfortWorld

- About Wool - Woolmark

- Polyester Fabric Guide: Explore the Look and Feel of Polyester - MasterClass

- Filature et filage : la préparation des fils - Textile Addict